This page will list documents related to the Queensland Coal Mining Board of Inquiry. Documents will be added as they are released.

The Board of Inquiry has made all reasonable efforts to:

- clearly label material where the copyright is owned by a third party. This does not include photos, images and video which are all regarded as third-party material.

- ensure that the copyright owner has consented to this material being published on this website.

Part I of the Report (PDF, 11MB)

The following documents and submissions are referenced in Part I of the Report.

Documents — Part I

Foreword

| Chapter | Page | Footnote | Document ID |

|---|---|---|---|

| Foreword | 3 | OCH.508.001.0001 – ACIL Tasman Final Report on the Queensland Mines Inspectorate Review 2 March 2005 (PDF, 5MB) |

Chapter 1

| Chapter | Page | Footnote | Document ID |

|---|---|---|---|

| Chapter 1 – Introduction | 21 | 37 | AAMC.100.002.0001 – Preliminary Briefing Paper from Anglo to Counsel Assisting the Board of Inquiry 12 July 2020 (PDF, 2MB) |

Chapter 2

Chapter 3

| Chapter | Page | Footnote | Document ID |

|---|---|---|---|

| Chapter 3 – The role of the Inspectorate | 83 | 303 | OCH.508.001.0457 – Noetic Group Regulatory Reform Review for NSW Department of Industry, Mine Safety December 2016 (PDF, 1MB) |

Chapter 4

Chapter 6

Submissions — Part I

Chapter 2

| Chapter | Page | Footnote | Party | Content in Submission |

|---|---|---|---|---|

| Chapter 2 | 50 | 142 | Anglo American Group companies 31/10/2020 | Accordingly, going forward, Anglo will deem every methane related DNRME HPI as being an Anglo HPI, whether or not it attracts a potential consequence rating of 4 or greater on the Risk Matrix. |

Chapter 3

| Chapter | Page | Footnote | Party | Content in Submission |

|---|---|---|---|---|

| Chapter 3 | 62 | 172 | Anglo American Group companies 31/10/2020 | Further, since the commencement of the Board’s Inquiry, Anglo has modified its reporting practices to include Departmental HPIs in all of its Monthly Performance Reports and Quarterly Performance Reviews. Mr Mitchelson, the Heads of Operations (including the Heads of Underground and Open-cut Operations), all General Managers and Head of Legal Australia now receive a daily email recording all Departmental HPIs which have occurred over the previous seven day period. This email was previously provided to the Heads of Operations. |

| 64 | 184 | Resources Safety and Health Queensland (RSHQ) 1/09/2020 | The establishment of RSHQ as a statutory body ensures its regulatory independence. It is not part of, or subject to oversight from, an administering department, such as DNRME. This also better ensures there is no competition or conflict between policy objectives around industry facilitation or promotion on one hand, and the regulation and protection of safety and health on the other. Although it was considered these functions were appropriately separated by the Regulator when it was a division of DNRME, the establishment of RSHQ removes the potential or perception of any conflict or erosion of independence. | |

| 67 | 201 | Mine Managers Association of Australia (MMAA) 17/07/2020 | Eighty percent, we believe, would be a fair reflection commensurate with industry standards. We fully accept that this level of remuneration is above that set within the Public Service however, this is an accurate reflection of the market forces currently at play in the mining industry and any lesser pay scale will result in a lower quality of candidate unless that individual has a highly developed altruistic view on life. | |

| 68 | 203 | Construction, Forestry, Manufacturing, Mining and Energy Union (CFMMEU) 1/09/2020 | It is not in the interests of safety for coal mine management personnel to be inspected by inspectors with inferior qualifications. If this requirement means that remuneration has to be increased to attract inspectors with first class certificates this should happen. | |

| 69 | 213 | Resources Safety and Health Queensland (RSHQ) 1/09/2020 | It is submitted the evidence demonstrates, and the Board would find, that the inspectors within the Inspectorate hold appropriate qualifications and experience to carry out their roles under the CMSHA. This is particularly so when regard is had to the genuine constraints within which RSHQ operates when attempting to recruit inspectors, including an extremely limited pool of potential candidates. | |

| 76 | 253 | Resources Safety and Health Queensland (RSHQ) 1/09/2020 | While the Inspectorate investigates each HPI reported to it, the level and detail of investigation that is required will vary depending on the circumstances of the HPI. A notification may be sufficiently serious to require mobilisation of an inspector to the mine, or it may require some other intervention, which can be as simple as asking questions, or determining if the mine has enough information about the exceedance to be satisfied they clearly understand the causal factors behind the exceedance. |

Chapter 4

| Chapter | Page | Footnote | Party | Content in Submission |

|---|---|---|---|---|

| Chapter 4 | 96 | 344 | Glencore Coal Assets Australia (GCAA) 30/10/2020 | GCAA wishes to clarify that its internal procedure stipulates that all HPIs that are notifiable in accordance with the Act are reported to senior management and senior executives of parent companies. This communication occurs by way of an email distribution list with the title “GCAA Reportable Incident Notification”. This distribution list has a large number of recipients within the GCAA management structure, including:

The notification requirement is set out in GCAA’s Regional Asset HSEC Standard 6.0 Incident (refer to document identifier OCH.507.001.0176). Please refer to our response to paragraph 1.183 for further detail. The email distribution list serves the function of reporting HPIs to senior management and also sharing information regarding HPIs within GCAA’s various operations. |

Chapter 5

| Chapter | Page | Footnote | Party | Content in Submission |

|---|---|---|---|---|

| Chapter 5 | 136 | 520 | Queensland Mines and Rescue Service (QMRS) 28/10/2020/td> | QMRS is a not for profit company owned by the Qld coal industry and funded by an industry membership levy and through ‘fee for service’ training. The levy is provided 70% from underground coal mines and 30% from surface coal mines.NSW Mines Rescue provides generic inductions, site specific inductions and refresher training to most underground mines in NSW, but not all, on a ‘fee for service’ commercial basis. The proximity of their training facilities to the mines and the quality of their trainers and their infrastructure capabilities in comparison to the alternative offerings sees a high take up of this training in the areas where they offer it. …QMRS, like NSWMR, could utilise its resources and the quality of its employees to provide a high quality product in the areas identified… Our core business is emergency response, and whilst self-escape training fits into that area of influence, much of the induction training is mine and operational skills specific and outside our core business. We would need to increase human resources to take on such additional activities.These areas of activity are highly cyclical, fluctuating with the production and price levels of the industry. In the last 6 years underground coal employment has fluctuated between 4700 and 6000 coal mine workers across all underground mines. Resourcing for such activities becomes problematic and requires a cost commitment through cycles to ensure a quality product is sustained. Such a commitment would need to be made by the industry if that is the desired direction that QMRS is to take. A benefit of QMRS involvement would be the multiple functionalities of the QMRS resources across emergency response training in both surface and underground coal, in non-coal mining training and for induction and refresher training. |

| 140 | 541 | Resources Safety and Health Queensland (RSHQ) 1/09/2020 | Section 60(8) of the CMSHA stipulates that the underground mine manager must appoint a person holding a first or second class certificate of competency or a deputy’s certificate of competency to be responsible for the control and management of underground activities when the manager is not in attendance at the mine. This provision must be read in the context of section 60(4), in that the SSE must appoint an alternate underground mine manager if the mine is to be managed in accordance with a commute system. A commute system means a schedule specifying the regular periods when underground mine managers and other supervisors and their alternates are to assume their duties at a coal mine. Despite this, RSHQ sees merit in considering whether it is sufficient for a person holding only a deputy’s certificate of competency to be responsible for the control and management of underground activities when the manager is not in attendance at the mine. It is submitted the Board might consider a recommendation to the effect that “Consideration be given to amending the CMHSA so as to stipulate that the person left in charge of an underground coal mine in the absence of the underground mine manager must hold either a first or second class certificate of competency.”. | |

| 142 | 547 | Anglo American Group companies 2/11/2020 | In the absence of a first and second class competency certificate, Anglo agrees with the Board’s recommendation that the RIIWHS601D competency be a competency required to be held by an SSE. In addition, Anglo submits that this also include competency in the mine emergency management system (commonly referred to as MEMS training) which is conducted by the QMSR. It is submitted that this is critical training for SSEs in circumstances where they generally assume the role of incident controller (or have an alternative but significant role) in the Incident Management Team and have a significant role in managing the mine’s emergency management systems. By mandating these competencies, Anglo submits that the SSE certification would be strengthened appropriately having regard to the purpose and obligations of the role as provided for in the Act. | |

| 142 | 548 | Resources Safety and Health Queensland (RSHQ) | The underground mine manager for an underground coal mine is required to have a first class certificate of competence for an underground mine.326 Despite the fact the SSE is required to appoint the underground mine manager,327 the SSE is not required by the CMSHA to be the holder of a first class certificate of competency. Having regard to the extensive obligations and responsibilities of the SSE, this appears incongruous. Further, the SSE is “the most senior officer employed or otherwise engaged by the coal mine operator for the coal mine” and “has responsibility for the coal mine”. Despite being the “most senior officer employed by the coal mine operator for the coal mine” section 60(6) of the CHMSA would prohibit a SSE (who does not hold a first class certificate of competency) from giving a direction to the underground mine manager about a technical matter in relation to theunderground mine. Having regard to the modern nature of underground mining, “technical matters” would appear to be of wide compass. The potential scenario of the most senior officer, who has responsibility for the mine, being unable to give a direction to their underground mine manager about a technical matter, reveals an undesirable tension, and has the potential to create difficulties in the discharge of the broad responsibilities imposed upon the SSE, and has the further potential to undermine the SSE’s accountability as intended by the legislative scheme. No such issues would arise if the most senior officer with responsibility for the coal mine was required to have a first class certificate of competency. There would appear to be numerous cogent reasons as to why a first class certificate of competency ought to be required to hold the position of SSE, and little is apparent by way of countervailing considerations.It is submitted that the Board might consider a recommendation to the effect that “Consideration be given to amending the CMSHA so as to require that a site senior executive for an underground coal mine be the holder of a first class certificate of competency”. | |

| 142 | 549 | Glencore Coal Assets Australia (GCAA) 30/10/2020 | GCAA agrees with this recommendation and suggests that it could be enhanced. If persons who hold a first class certificate of competency were also to become automatically eligible to receive an SSE competency, this would encourage more people to undertake the body of work to obtain the more difficult first class certificate of competency in order to get the SSE competency. | |

| 142 | 550 | Anglo American Group companies 2/11/2020 | Whilst it is appreciated by Anglo that it may be considered ideal that all SSEs hold first class certificates, Anglo submits that a person with the role of SSE does not require this qualification in order to competently perform the role. |

Chapter 6

| Chapter | Page | Footnote | Party | Content in Submission |

|---|---|---|---|---|

| Chapter 6 | 176 | 644 | Glencore Coal Assets Australia (GCAA) 28/10/2020 | GCAA notes that, as recognised in paragraph 1.153 of the draft chapter and as noted in the evidence submitted by GCAA to the Inquiry, there are also leading indicators that are included in the Managerial Customer Service Indicators, the Individual Customer Service Indicators and the Customer Feedback components of the performance appraisal for individual employees. It is not appropriate to suggest that the use of leading health and safety indicators is limited to the Health and Safety Index component of the performance appraisal. |

Part II of the Report (PDF, 20MB)

The following documents and submissions are referenced in Part II of the Report.

Documents — Part II

Summary of Findings and Recommendations

| Chapter | Page | Footnote | Document ID |

|---|---|---|---|

| Summary of Findings and Recommendations | 19 | 1 | RSH.002.095.0001 – Email dated 04/07/2019 Grosvenor Mine to Keith Brennan re CH (PDF, 2MB) |

| 19 | 2 | RSH.002.138.0001 – Mine Record Entry (MRE) for Inspection at Grosvenor mine on 2 July 2019 (PDF, 1MB) | |

| 27 | 3 | SST.002.001.0001 – Statutory Declaration of Stephen Smith (PDF, 700KB) |

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Chapter 7

Chapter 8

| Chapter | Page | Footnote | Document ID |

|---|---|---|---|

| Chapter 8 – The nature and cause of the serious accident: The first pressure wave | 230 | 820 | RSH.002.233.0001 – Fowler, J. & Sharma, P., Dynamics of Wind Blasts in Underground Coal Mines (2000) Project No. C6030 Report, Australian Coal Association Research Program (PDF, 6MB) |

| 232 | 827 | RSH.001.049.0001 – GRO-10685-HMP-LW104 First Goaf (PDF, 6MB) |

Chapter 9

Chapter 10

| Chapter | Page | Footnote | Document ID |

|---|---|---|---|

| Chapter 10 – Proactive inertisation of the active goaf, and strategies to limit oxygen ingress | 335 | 1156 | BAL.001.001.0001 – Dr Rao Balusu, Responses to the Questions from the Queensland Coal Mining Board of Inquiry (PDF, 486KB) |

| 336 | 1157 | BOI.036.001.0001 – Balusu, R., Ren, T. & Humphries, P., Proactive Inertisation Strategies and Technology Development (2005) Project No. C12020 Report, Australian Coal Association Research. (PDF, 3MB) | |

| 337 | 1165 | RSH.003.001.1645 – MRE on 11/06/2020 – Grosvenor Coal Mine Investigation (PDF, 670KB) | |

| 342 | 1181 | BOI.036.002.0001 – Ren, T. & Balusu, R., Proactive goaf inertisation for controlling longwall goaf heatings (2009) Procedia Earth and Planetary Science volume 1. (PDF, 788KB) |

Chapter 11

| Chapter | Page | Footnote | Document ID |

|---|---|---|---|

| Chapter 11 – Labour hire and contract employment arrangements | 369 | 1241 | BOI.001.004.0001 – “Report on a number of matters with regard to the Board of Inquiry Investigation into the methane incident at the Anglo American Grosvenor Mine at Moranbah on 6 May 2020 and related matters” by Emeritus Professor Michael Quinlan (PDF, 1MB) |

| 384 | 1305 | AAMC.001.036.0001 – Statement of Warwick Jones dated 28/07/2020 (PDF, 8MB) | |

| 385 | 1311 | OCH.507.002.0001 – Statutory Declaration of Kylie Ah Wong (PDF, 6MB) | |

| 385 | 1312 | OCH.504.001.0084 – Oaky North 2019 Workforce Profile (PDF, 93KB) | |

| 385 | 1313 | LBE.001.001.0001 – Statement of Ben Hudson Lewis dated 20/08/2020 (PDF, 138KB) | |

| 386 | 1316 | OCH.504.001.1027 – List of labour hire companies that provided supplementary labour at Oaky North Mine during December 2019 (PDF, 399KB) | |

| 394 | 1368 | OKR.003.017.0001 – Site Safety Audit – One Key Resources |

Chapter 12

| Chapter | Page | Footnote | Document ID |

|---|---|---|---|

| Chapter 12 – Industry Safety and Health Representatives | 412 | 1426 | HLJ.001.001.0001 – Affidavit of Jason Hill (PDF, 9MB) |

| 412 | 1426 | WST.001.001.0001 – Affidavit of Stephen Woods (PDF, 6MB) | |

| 414 | 1436 | DGR.001.001.0001 – Statement of Gregory Alan Dalliston dated 16/08/2020 (PDF, 224KB) | |

| 418 | 1472 | CRE.001.001.0001 – Statement of Reece Campbell (PDF, 260KB) | |

| 418 | 1472 | CRE.001.002.0001 – Addendum Statement of Reece Campbell (PDF, 148KB) | |

| 429 | 1535 | BJO.001.001.0001 – Affidavit of Joe Barber (PDF, 2MB) | |

| 434 | 1601 | HRI.001.001.0001 – Affidavit of Richard Harris (PDF, 1MB) | |

| 435 | 1618 | HJI.001.001.0001 – Affidavit of James Hoare (PDF, 295KB) |

Submissions — Part II

Chapter 1

| Chapter | Page | Footnote | Party | Content in Submission |

|---|---|---|---|---|

| Chapter 1 | 44 | 11 | Anglo American Group companies 12/04/2021 |

It has not been possible for Anglo, or members of the Senior Leadership Team (SLT) at Grosvenor to participate properly in this Inquiry. That is because the Board is tasked with performing its function at the same time that Resources Safety and Health Queensland (RSHQ) is investigating the 6 May 2020 incident and determining whether a prosecution process may follow. Neither Anglo nor the SLT can or should be obliged to help RSHQ to formulate a criminal case against them. Meaningful participation in the Board’s hearings carries that risk. So much was recognised by the Board’s acceptance of privilege claims made by Anglo employees and contractors. |

| 44 | 12 | Anglo American Group companies 12/04/2021 |

…potentially impacted parties have been forced to participate in these proceedings with their hands, in effect, tied behind their backs. In particular, they have not been able to put forward alternatives to the [Resources Safety and Health Queensland – RSHQ] theory of the case through cross- examination, calling witnesses, and making submissions, to the same extent that they might have done had they not been the subject of concurrent criminal investigations into the same subject matter as that which the Board is investigating. They have not been able to do so because doing so would have afforded the opportunity to RSHQ to be informed of the weaknesses in its theory of the case and of possible answers to that theory. Essentially, to participate fully would have meant potentially assisting an investigating agency to make its case. | |

| 45 | 13 | Anglo American Group companies 21/05/2021 |

In many cases, the likelihood of prosecution is seen by prospective defendants as so great that those defendants see little point in drawing attention to exculpatory evidence in the knowledge that the likely effect of doing so will only lead to the prosecutor seeking to negate that evidence in what is, given the willingness with which prosecutions are taken by this regulator [Resources Safety and Health Queensland], a virtually certain prosecution. In cases of that kind, the “choice” faced by those prospective defendants is between insisting on their rights and prejudicing their defence. That is not a real choice. |

Chapter 4

| Chapter | Page | Footnote | Party | Content in Submission |

|---|---|---|---|---|

| Chapter 4 | 103 | 290 | Anglo American Group companies 21/05/2021 |

…Mr Self’s evidence was that neither increased pre-drainage effort (specifically, pre-drainage of unworked seams) or increased intensity of post-drainage would have changed the fact that the LW104 goaf would contain a large volume of methane. |

| 109 | 307 | Anglo American Group companies 12/04/2021 |

One hole was attempted from [maingate] MG104 from 22 [cut-through – c/t] but was

abandoned when 837 metres of drill string became stuck in the P seam inbye of MG104 22 c/t. In relation to this series of events, it is important to note that goaf well GR04V002A was completed as a vertical hole planned to be intersected by a P seam lateral which was one of two planned P seam lateral holes that were abandoned prior to the start-up of LW104 due to difficulties experienced in drilling these lateral holes in the Fooey Fault area. This drilling work was completed between December 2019 and February 2020 but was ultimately abandoned when a significant portion of the drill got stuck in the landform. As is observed above, one of the contributing factors identified in relation to this series of [high potential incidents] was insufficient drainage of the P seam which occurred as a result of the failed attempt to drill twin lateral wells into the seam prior to LW104 commencement. |

|

| 113 | 325 | Anglo American Group companies 21/05/2021 | In particular, the alleged failure to consider a strategy proposed by an expert in evidence to the Board pre-supposes the strategy advanced was a “credible” one. No evidence was advanced in the hearing as to the scientific validity or credibility of Dr Williams’ wholly theoretical strategy, or of any testing, trialling or validating support of the notion that “relaxed strata wells” would have the desired outcome, in circumstances where Anglo regularly engaged external experts, such as Dr Moreby, to consider these issues in more detail at the time. | |

| 116 | 336 | Anglo American Group companies 21/05/2021 | While it is accepted that there was no specific risk assessment conducted in relation to the risk of spontaneous combustion as result of the change to 25 metre spaced goaf wells [for LW104], this does not mean that the risk of spontaneous combustion was ignored by the [Grosvenor] Mine. | |

| 120 | 354 | Anglo American Group companies 21/05/2021 | The figure of 112,000 tonnes per week on average is derived from the total production figure [for LW103] of 814,966 tonnes for the period from 16 December 2018 to 5 February 2019 recorded in the report of Dr Williams at page 41. This figure is disputed and Anglo advises the Board that the correct figure for that period is 896,786 tonnes in total. This figure averaged out over the 51 days in that period amounts to about 123,088 tonnes per week on average. This is consistent with Mr Mitchelson’s estimate that the production figures for LW103 were about 135,000 per week on average. | |

| 124 | 364 | Anglo American Group companies 21/05/2021 | …using an arbitrary SGE value of 25 cubic metres per tonne and simple theoretical mathematical calculations to justify certain ventilation and post drainage requirements is subject to error and no attempt has been made to compare these calculations with the actual real time data captured by [the Grosvenor data monitoring system] CITECT at the time of the [high potential incidents] (which are influenced by dynamic macro and micro-operational factors). |

Chapter 5

| Chapter | Page | Footnote | Party | Content in Submission |

|---|---|---|---|---|

| Chapter 5 | 165-166 | 542 | Anglo American Group companies 21/05/2021 | The 100,000 tonnes per week that Mr Mitchelson referenced was a budget, not a mandated cap on production. As Mr Mitchelson identified in his evidence, the budget was intended to reduce pressure on the [Grosvenor] Mine given the challenging site conditions at the commencement of LW104. In this context, the reduced target for LW104 can only sensibly be construed as an average, given that in the complex operating environment that is the operation of a longwall, production will be more in some weeks and less in other weeks depending on the conditions faced at any particular time. The estimate of production rates for LW103 provided by Mr Mitchelson should also only be taken as an estimate of what was being produced over a similar section of the longwall. It was not intended to be a ‘pillar for pillar’ comparison over precisely the same period of time and, when properly understood, is not mistaken. |

| 167 | 548 | Anglo American Group companies 21/05/2021 | What can be seen from the LW104 production documents is that over the 10 weeks it was in operation, the total amount budgeted for was 935,661.36 tonnes. This averaged out over the 10 weeks of operation amounts to 93,566.13 tonnes per week, which is under the 100,000 tonnes per week target that Mr Mitchelson spoke about in his evidence. This indicates that the intention to remove pressure on [the Grosvenor] site by reducing the budget was implemented and effective. | |

| 168 | 549 | Anglo American Group companies 21/05/2021 | In terms of actual production, 866,780 tonnes were produced at the [Grosvenor] Mine over the 66 days [LW104] was in operation. This amounts to about 9.4 weeks. Therefore, the average weekly production rate was about 92,210.6 tonnes, again below the 100,000 tonne budget target set for the Mine, as described by Mr Mitchelson in his evidence. This is considerably lower than the average weekly production rate of about 123,088 tonnes per week for LW103 and is consistent with the approach described by Mr Mitchelson in his evidence before the Board of a reduction in the rate of production to meet the particular circumstances in which the Mine was operating. | |

| 167 | 550 | Anglo American Group companies 21/05/2021 | …a conclusion that production rates ought to have been reduced to avoid [high potential incidents] occurring is inaccurate, unwarranted and is not supported by the evidence. |

Chapter 8

| Chapter | Page | Footnote | Party | Content in Submission |

|---|---|---|---|---|

| Chapter 8 | 279 | 956 | Anglo American Group companies 12/04/2021 | The limit of reporting of ethylene for Simtars is 20 [parts per million – ppm]. Although Mr Muller tried to downplay that point in his evidence, the reality is that Simtars has determined that it would not even report below 20 ppm if asked to on the same Gas Chromatograph results. Further, the limit of detection is 1 ppm. That is, it has been determined that at less than 1 ppm it is not possible to differentiate safely between an actual ethylene spike and the results that a test gas sample in a chromatograph would give. Mr Muller accepted in questions from Senior Counsel for [Resources Safety and Health Queensland] that he would only have expected the operators to have picked up “some” of the sub-ppm detections that were found by Simtars on its re-testing. |

| 280 | 959 | Anglo American Group companies 12/04/2021 | Given that those doing the re-testing are Simtars chemists, that Simtars itself trains the operators and that the limit of detection is 1 [part per million – ppm], no weight could conceivably be given to the propositions that (a) any fault lies with the Operators or (b) that these were in fact detections of sub ppm amounts of ethylene. | |

| 280 | 960 | Anglo American Group companies 12/04/2021 | Given that the (so-called) unidentified ethylene spikes ranged from .05 [parts per

million – ppm] to .28 ppm, the range within which Mr Muller identified a Control Room Operator would or

would not be able to identify such a spike is (a) very small and (b) sits (at its highest) at five times

less than the limit of detection for ethylene (discussed below). Further, the limit of reporting of ethylene for Simtars is 20 ppm. That is, Simtars has determined that it would not even report below 20 ppm if asked to do so on the same Gas Chromatograph results. Further, the limit of detection is 1 ppm. That is, Simtars has determined as part of its [National Association of Testing Authorities – NATA] accreditation that at less than 1 ppm it is not possible to safely differentiate between an actual ethylene spike and the results that a blank test gas sample in a chromatograph would give. To place any weight on so-called ethylene spikes at a sub-ppm level in those circumstances would be unfair and dangerous. |

Chapter 9

| Chapter | Page | Footnote | Party | Content in Submission |

|---|---|---|---|---|

| Chapter 9 | 320 | 1119 | Dywidag-Systems International Pty Ltd trading as DSI Underground 23/05/2021 | It is unlikely that the use of [polyurethan resin – PUR] on longwall104 prior to the

events of 6 May 2020 created an ignition event which induced spontaneous combustion. That is so because:

(a) broadly speaking, there is insufficient evidence which establishes that the proper application of PUR is capable of creating a heat source which could culminate in spontaneous combustion of [Goonyella Middle Seam] coal; and (b) with specific reference to the events of May 2020 at Grosvenor Mine, there is no evidence that the actual application of PUR at the Grosvenor mine created a heat source which culminated in an event of spontaneous combustion on longwall104 on 6 May 2020. |

| 320 | 1120 | Dywidag-Systems International Pty Ltd trading as DSI Underground 14/04/2021 |

Only two witnesses principally addressed the potential for [polyurethane resin – PUR]

induced heating/spontaneous combustion: (a) Dr Basil Beamish; and (b) Mr Bipin Parmar. Neither of those witnesses was present at the [Grosvenor] mine at any relevant time. Neither of those witnesses was familiar with the physical characteristics of the Grosvenor mine [longwall 104] face as at May 2020 to enable them to offer an informed opinion as to the likely cause of the explosion. |

|

| 321 | 1124 | Dywidag-Systems International Pty Ltd trading as DSI Underground 14/04/2021 |

…it is worth recalling that the factual assumptions that underpin Dr Beamish’s

hypothesis required all of the following elements, existing cumulatively in the same temporal timeframe:

(a) a piece of coal about the size of a “very small tennis ball or soccer ball”; (b) completely encapsulated in [polyurethane resin – PUR]; (c) heated via a process of thermal transfer (which no witness, including Dr Beamish was qualified to describe in any detailed manner) to the point of thermal runaway (the precise temperature of which was not identified in any satisfactory way) where such heating process necessarily overcame “the natural inhibition from moisture and mineral matter in the coal” as well as any ameliorative effects of moisture, airflow, or heat distribution to the surrounding environment occasioned by the actual mine face conditions (none of which were known); (d) exposed to sufficient oxygen to sustain combustion (notwithstanding that the “ball” of coal was, necessarily and simultaneously, encapsulated in PUR according to the second element, and where its exposure to oxygen was “very small”; and where, once the shields move past the place where the coal is, it became “oxygen deficient”) but if the effected coal were to cave into the goaf immediately behind the shields, there might be some oxygen at a higher level than in the roof [emphasis added]; and (e) where none of the following common indicia of burning coal were observed by the coal workers present on the coal face immediately prior to the explosion on 6 May 2020: (i) glowing; (ii) smoke; (iii) odour; or (iv) heat haze. |

|

| 321 | 1124 | Dywidag-Systems International Pty Ltd trading as DSI Underground 14/04/2021 |

…arguably it is the second limb where the breakdown of the Thermal Runaway Hypothesis is most evident. For the purposes of his March 2021 report, Dr Beamish had expressly relied on a statement in his 2009 report (co-authored with Messrs Cuddihy and Cliff) which purported to contend that coal encapsulated in curing [polyurethane resin – PUR] would thereby adopt the same maximum temperature as the PUR. During cross-examination, Dr Beamish acknowledged that such a proposition was “inaccurate” and “not completely correct”. For the adjacent coal to be heated above its ambient temperature, it must draw energy in the form of heat away from the curing PUR. Accordingly, the adjacent coal can never be the same heat as the maximum curing temperature of PUR, a proposition that was accepted by Dr Beamish notwithstanding the contrary statement in his reports dated 2009 and 2021. | |

| 321 | N/A | Dywidag-Systems International Pty Ltd trading as DSI Underground 14/04/2021 |

The proposition that the curing process of the [polyurethane resin], in mine conditions, heated the [Goonyella Middle] seam coal to 100°C is, at its absolute highest, a hypothetical possibility, but one which has thus far not been demonstrated by testing, even though testing of the curing process was undertaken by SIMTARS and the results postulated by Dr Beamish could not be verified. The hypothesis was, according to Dr Beamish, one which necessitated further investigation. |

Chapter 11

| Chapter | Page | Footnote | Party | Content in Submission |

|---|---|---|---|---|

| Chapter 11 | 370 | 1243 | Construction, Forestry, Maritime, Mining and Energy Union (CFMMEU) 09042021 | The evidence…demonstrates the apotheosis in terms of the exploitation of the labour

hire model exhibited at the Grosvenor Mine where the labour hire model has nothing to do with managing

peaks and troughs. It further supports Recommendation 12 made in the First Tranche Submissions of the

CFMMEU which is as follows: Recommendation 12 All possible measures should be taken to achieve the objective of coal mine workers engaged to perform production and engineering activities being employed by the mine operator, and for the most part, on a full-time permanent basis. The only exception to this should be for genuine short-term requirements for labour and specialised tasks. |

| 393 | 1363 | Resources Safety and Health Queensland 27/10/2020 | Although [labour hire company One Key Resources Pty Ltd] does not appear to consider it

has any obligations for its employees’ safety under section 43 or 47 of the [Coal Mining Safety and

Health Act 1999 (Qld) – the Act] (or otherwise under the Act), RSHQ does not share that view. The Labour Hire Chapter does not detail the general obligation contained in section 39(1) of the Act. RSHQ submits that the general obligation contained in section 39(1) of the Act should be acknowledged in the Labour Hire Chapter in considering the potential obligations of labour hire agencies and contractors. RSHQ submits that care needs to be taken to ensure that the potential current applicability of that provision to labour hire agencies and contractors is highlighted, particularly in circumstances where the proposed amendment to the Act so as to incorporate a provision in similar terms to section 19 of the Work Health and Safety Act 2011 (Qld), has not yet been actioned and, if any act occurs in the interim, it would be the current provisions that would operate. |

|

| 393 | 1364 | One Key Resources Pty Ltd 01/09/2020 |

It may be submitted, as had been foreshadowed by Counsel assisting, [Mr Jeffrey Hunter QC], that there ought be a recommendation correcting the situation that exists at present whereby labour hire companies do not have any workplace health and safety obligation such as that to be found in [section] 19 of the [Work Health and Safety Act 2011 (Qld)]. One Key supports such a recommendation. |

Chapter 12

| Chapter | Page | Footnote | Party | Content in Submission |

|---|---|---|---|---|

| Chapter 12 | 415 | 1448 | Queensland Resources Council 01/09/2020 | The disconnect between the functions of the union appointed [Industry Safety and Health Representatives – ISHRs] elected by a small proportion of the overall coal mine workers and [Site Safety and Health Representatives – SSHRs], is evident from the Inquiry hearings to date. |

| 415 | 1449 | Queensland Resources Council 01/09/2020 | The QRC has previously raised the concern that the [Industry Safety and Health Representative] powers are at worst open to abuse for industrial purposes. | |

| 415 | 1450 | Glencore plc and Oaky Creek Holdings Pty Ltd 03/09/2020 | Glencore (and OCH) supports the position of Industry Safety and Health Representatives (ISHR). However, in its 2013 submission on the Regulatory Impact Statement for the Queensland Mine Safety Framework Glencore expressed the view that ISHRs would be best placed to perform their role as employees of the DNRME, rather than employees of the [Construction, Forestry, Maritime, Mining and Energy Union – CFMMEU]. This would make the ISHRs more accessible to all mine workers, and more accountable to the entire industry for safety management in Queensland’s coal mines. | |

| 416 | 1451 | Glencore plc and Oaky Creek Holdings Pty Ltd 03/09/2020 | Under the Mining and Quarrying Safety and Health Act 1999 (Qld), the District Workers’

Representatives are appointed by the Minister with the role of the unions being limited to nominating

individuals for appointment. By contrast, under the [Coal Mining Safety and Health Act 1999 (Qld)] it is the [Construction, Forestry, Maritime, Mining and Energy Union – CFMMEU] that appoints the [Industry Safety and Health Representatives -ISHRs]. Glencore’s view is that the metals legislation is superior to the [Coal Mining Safety and Health Act 1999 (Qld)] approach because: (a) it reduces the propensity for industrial conflict, given that the appointments are made by the Minister; (b) it fosters greater accountability in the role of the ISHR, as under the [Coal Mining Safety and Health Act 1999 (Qld)] there is less likelihood that any concerns with an ISHR’s conduct will be escalated within the union. |

|

| 416 | 1456 | Construction, Forestry, Maritime, Mining and Energy Union (CFMMEU) 03/09/2020 | Section 109 of the [Coal Mining Safety and Health Act 1999 (Qld)] provides for election

of [Industry Safety and Health Representatives – ISHRs] through the CFMMEU. One alternate system raised in cross examination was by way of the erroneous question put based on the proposition that district workers representatives appointed under the Mining and Quarrying Safety and Health Act 1999 (Qld) could be non-union. The correct position is that district workers representatives appointed under [section] 108 of the Mining and Quarrying Safety and Health Act 1999 (Qld) must be first nominated by an industrial organisation with members in the mining industry. A similar position is provided for in the coal mining industry in NSW by virtue of [section] 28 of the Work Health and Safety (Mines and Petroleum Sites) Act 2013 (NSW) which provides for appointment of ISHRs from persons nominated by the CFMMEU. Another alternate system that was suggested by questions to Professor Quinlan and Mr Dalliston was election of ISHRs by all coal mine employees without reference to CFMMEU membership at all. Professor Quinlan and Mr Dalliston categorically rejected the merits of that alternate system, pointing to the important role played by CFMMEU representation in the safety process and how this is consistent with union representation and support in industry generally. … Union involvement was, and remains, integral to the operation of the [Site Safety and Health Representative – SSHR] and ISHR system. Professor Quinlan specifically referred to the CFMEU’s continued contribution to the system. Further he said that the positive role of unions in [occupational health and safety] is well known and evidence based. He also said that studies in coal mining have found a significant link between union presence and health and safety outcomes. Further, the role of the union, SSHRs and ISHRs have been the subject of detailed research, including internationally published and peer-reviewed literature, as recently as 2014, specifically dealing with the system that operates in Queensland. … Intense scrutiny of submissions calling for changes to the ISHR election methods should be applied. Mine operators and employees do not want democracy in the system, they want to change the system entirely to preclude effective union involvement and to engage instead in direct behaviour-based systems that undermine representative safety and health systems. … Professor Quinlan’s review also found that Australian arrangements in relation to the international study, found them to represent “worlds best practice”. It is important to note that that finding was made despite known gaps, including the absence of SSHRs at less unionised mines. Inhibiting the role of the CFMMEU would undermine the safety and health of coal mine workers. … Further, there is no evidence at all that either of the mentioned alternate systems would be more in the interests of health and safety. |

|

| 420 | 1488 | Construction, Forestry, Maritime, Mining and Energy Union (CFMMEU) 03/09/2020 | Thirdly, there is no reason why unannounced inspections, the merits of which are

discussed above, should not also be conducted by [Industry Safety and Health Representatives – ISHRs].

Messrs Dalliston, Hill, Woods and Barber all gave unchallenged evidence that [section] 119(1)(b) of the

[Coal Mining Safety and Health Act 1999 (Qld)] should be amended to provide for unannounced inspections.

In general industry union permit holders may in some circumstances make unannounced inspections with the

proviso that as soon as is reasonably practicable after entering the workplace notice of the entry is

given: see for example s 119 of the Work Health and Safety Act 2011 (Qld). Section 119(1)(b) of the [Coal Mining Safety and Health Act 1999 (Qld)] should be amended to remove the requirement for reasonable notice and provided for notice to be given as soon as reasonably practicable after entry to the mine. |

|

| 420 | 1490 | Queensland Resources Council 01/09/2020 | An ISHR only has to have formed a belief that there is an unacceptable level of risk before exercising their powers; there is no requirement for that belief to even meet the test of reasonableness. The only constraint on the exercise of their powers is a requirement to give reasonable notice prior to entry to a workplace. Inspectors on the other hand are justifiably able to undertake random and unannounced inspections. The [Construction, Forestry, Maritime, Mining and Energy Union – CFMMEU] has previously argued for the removal of the requirement for ISHRs to give reasonable notice of entry. The QRC is of the view that this issue will inevitably be raised again and would like to again place on the record that our position remains that in the high-risk coal mining industry it is essential that the requirement to provide reasonable notice is retained. | |

| 420 | 1491 | Queensland Resources Council 01/09/2020 | Entry [to a workplace] cannot and should not be prevented, but the current provisions ensure that such entry will be undertaken safely. | |

| 421 | 1494 | Construction, Forestry, Maritime, Mining and Energy Union (CFMMEU) 03/09/2020 | …both Mr Hill and Mr Woods also gave evidence about difficulties in being allowed to

copy documents examined under [section] 119(1)(c) of the [Coal Mining Safety and Health Act 1999 (Qld)].

They have the power in [section] 119(1)(c) to examine, but arguably not copy, relevant documents. They

separately have the power in [section] 119(1)(d) to copy safety and health management system documents,

which seems to be a narrower category. Copies of documents falling into the former category are arguably

able to be obtained via [sections] 119(1)(e), (2) and/or (3) but it is not clear. To put the position beyond doubt [section] 119(1)(c) and (d) could both be re-worded to provide “examine and copy”. |

|

| 421 | 1495 | Construction, Forestry, Maritime, Mining and Energy Union (CFMMEU) 03/09/2020 | …Mr Hill also suggested that [Industry Safety and Health Representatives – ISHRs]

should have the power to issue directives to reduce risk under [section] 166 of the [Coal Mining Safety

and Health Act 1999 (Qld)]. It is absurd that the ISHRs have the power to issue a directive to stop work

but not have power to issue a less drastic directive to reduce risk. As Mr Dalliston, who agreed with

this proposal, pointed out, this was agreed to by the Inspectorate ten years ago but never

implemented. … Section 166 of the [Coal Mining Safety and Health Act 1999 (Qld)] should be amended to give ISHRs the power to issue directives to reduce risk. |

Expert extracts — Part II

Chapter 1

| Chapter | Page | Footnote | Content in Expert material |

|---|---|---|---|

| Chapter 1 | 51 | 39 & 40 | [Specific gas emission is] a term almost universally misunderstood in the coal industry and confused with gas make. It is a static “specific” parameter – the total quantity of gas emitted by a longwall, including tail down emission after mining, divided by the total tonnes mined. Units are in m3/t. It is usually calculated using European methods, which are very much outdated and not well applicable to Australian conditions. |

| 51 | 41 | Gas make is the relationship between gas generated from all sources in m3/t and related production in tonnes. It is far more useful than [specific gas emission]. Models such as GeoGAS’s pore pressure model produce the gas make curve which can be calibrated against known gas make. For an operating mine, gas make equations plugged into the model…can be quite useful. |

Chapter 4

| Chapter | Page | Footnote | Content in Expert material |

|---|---|---|---|

| Chapter 4 | 94 | 250 | Gas can enter the goaf from the higher seams (FH, QA, QB) by migration long bedding planes, into fractures bounding the caved/relaxed area above the extracted GM seam. |

| 95 | 253 | Figure 27 in the Board of Inquiry Report Part II. | |

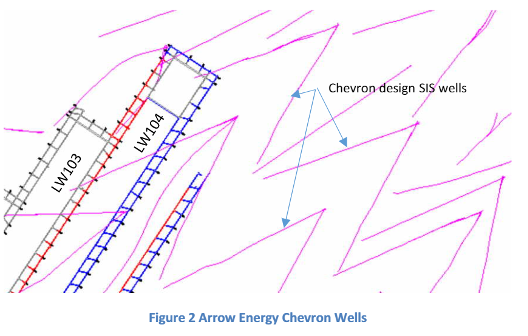

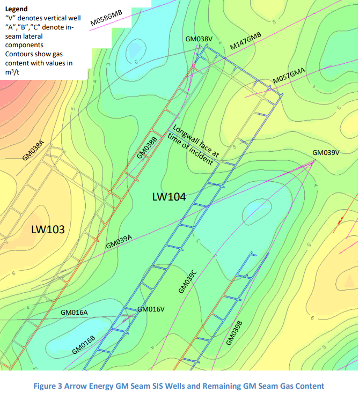

| 96 | 256 |

A unique feature of the mining environment is the partial predrainage of the P and GM seams by Arrow Energy. The company was extracting coal seam gas for utilisation and it took place over a period of 10~15 years ahead of mining. The surface to in-seam (SIS) wells employed were mostly of chevron design

(Figure 2) with usually two SIS laterals intersecting a vertical production well. The chevron pattern results in variable lateral well spacing with resulting non uniform gas extraction.  The resulting remaining gas contents are as modelled by Arrow Energy (Figure 3). The level and lack of uniform predrainage as required by coal mining necessitated supplementary underground in- seam (UIS) predrainage, gas extraction.  | |

| 96 | 259 & 260 |

As covered in the section on [Goonyella middle] seam predrainage, a high level of predrainage has been achieved prior to commencement of mining in LW104. The P seam tests (actually GR, PL1 and PL2 seams) showed partial predrainage achieved by the P seam Arrow wells (~28% of gas drained to Qm of 7.4 m3/t from virgin ~10.4 m3/t). This is in good agreement with modelled residuals from Arrow wells (~8 m3/t). | |

| 98 | 264 |

Prediction of gas make is notoriously difficult. Various empirical and numerical gas emission models exist and all have flaws, since the quantification of the gas reservoir and mechanism of gas release are complex and the models are simplistic by nature. The author [Mr Andrew Self] has experience in gas emission prediction and has observed predictions which were widely disparate from reality in practice. This relates both to under and over-estimation. An accuracy tolerance of ±50% is not unusual in the author’s experience at an early stage in the project, where calibration data are not available. … Gas emission predictions early in a project are normally based on sparse data, limited by the number of gas samples taken from bore-holes prior to mine development. As the project progresses, measured data become available and estimates become more accurate. Permeability determinations are rarely made, meaning that the rate of transmission of gas through the coal seams cannot be determined, limiting the ability to predict and design pre-drainage systems. | |

| 98 | 265 & 266 | As stated, all gas emission predictive models, whether numerical or empirical, are flawed. Predictions of gas emission should therefore be treated as indicative at best without calibration data from actual, measured gas emission rates. This is clearly not possible at feasibility study level or, in fact, until longwall mining experience has been gained. Comparison with similar operations elsewhere is useful, but not necessarily reliable, as important factors such as desorption pressure may vary. | |

| 98 | 269 |

The Flügge method of assessing longwall gas emission is one of a suite of European empirical methods developed in the 1950’s to 1970’s. It is based upon mining conditions and volumes very different from those experienced in Australia (refer description and critique in Qu, Balusu, Wilkins and Moreby

2019 – ACARP project report C25065). It defines the degree of emission from seams above and below the working seam using a geometry based on empirical conditions in German coal mines with adjustment for the intensity of gas drainage. It takes no account of gas desorption pressure or gas saturation. Once the degree of emission from the various gas sources is defined, it still remains to show how this emission will manifest itself as in the production of gas make curves. As outlined in [Dr Ray Williams’ first] report 2020-001, there are much better, more up-to-date, targeted options that can be employed (eg pore pressure modelling, gas make equations as detailed in appendix A2 of report 2020-001). All these models involve a high degree of uncertainty requiring calibration against actual mining conditions. The level of uncertainty can be quantified and ranked using…probability modelling. | |

| 100 | 273 | It seems that the Flügge gas emission prediction model was optimistic since LW104 SGE reached around 25 m3/t. Given the lead time between prediction and actual longwall mining, this is not entirely unexpected due to the limitations of the Flügge gas emission prediction model and the lack of opportunity to calibrate the gas emission model, since longwall extraction had not commenced. | |

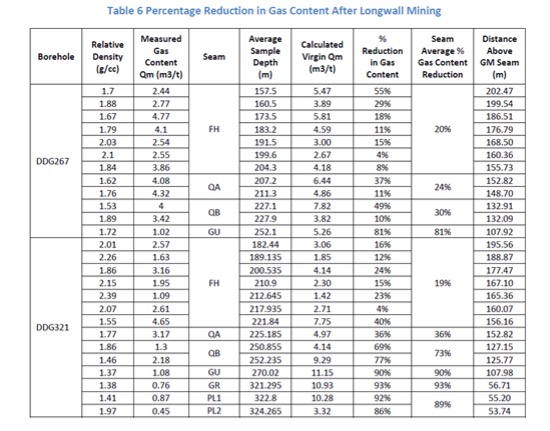

| 101 | 278 |

An assessment of gas emission is made utilising the gas reservoir properties (gas content, saturation, desorption pressure, gas reservoir size) and developing an understanding of emission characteristics from back analysis of LW103 and LW104 emission. The latter includes assessment of airway emission

and goaf well drainage. Critical use is made of two gas content test, surface drilled, boreholes drilled into previously formed goafs in LW101 and LW103. … Two boreholes were drilled and cores for gas content testing taken, as follows: – Borehole DDG267 LW101 goaf on 25th July 2017. Previously mined under 23rd July 2016, 367 days earlier. – Borehole DDG321 LW103 goaf on 10th August 2019. Previously mined under 23rd February 2019, 168 days earlier | |

| 101 | 279 | Figure 36 in the Board of Inquiry Report Part II. | |

| 101 | 280 | As indicated in [Dr Williams’ first] report, relaxed strata wells may obviate the need for additional P seam predrainage, but until it is proven as such, P seam predrainage should be a high priority consideration. | |

| 101 | 281 | Predrainage of the P seam is desirable but relatively difficult (drilling conditions, transmissibility across bands). | |

| 103 | 288 | However, other mines extracting the [Goonyella middle seam] do not pre-drain the P seam. Given the lack of precedent it is not surprising that P Seam pre-drainage was not pursed. | |

| 103 | 289 | Predrainage is generally more effective than post-drainage in that capture is more assured. | |

| 103 | 291 | Figure 36 in the Board of Inquiry Report Part II. | |

| 108 | 302 | The well was blind ended which precluded pumping and gas predrainage. | |

| 108 | 305 | Figure 34 in the Board of Inquiry Report Part II. | |

| 110 | 310 |

Over the mined area of LW104, the Fair Hill (FH) seam has a thickness of 45 m (180 m to 225 m depth) and provides a large gas reservoir (~ 3 times the size of the virgin gas content [Goonyella middle] seam). …  | |

| 110 | 311 |

The importance of a (coal seam and coaly material) gas source is determined by: – Its proximity to the working seam – The magnitude of its [gas reservoir size] – The gas saturation and desorption pressure | |

| 110 | 312 | Over the mined area of LW104, the Fair Hill (FH) seam has a thickness of 45 m (180 m to 225 m depth) and provides a large gas reservoir (~ 3 times the size of the virgin gas content [Goonyella middle] seam). | |

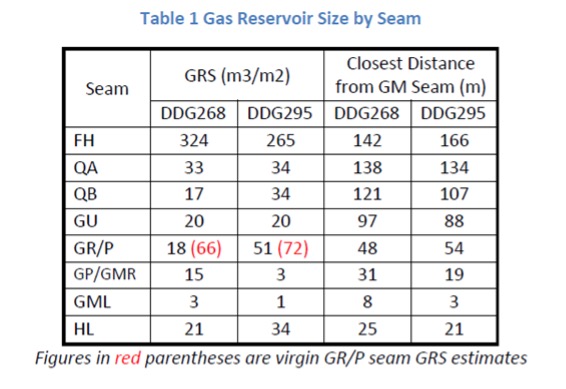

| 110 | 313 |

Most notable is the very large gas reservoir size of the FH seam (Figure 26, Table 1), around three times the [gas reservoir size] of the virgin [Goonyella middle] seam. | |

| 110 | 314 | Gas desorption pressure magnitude is a driving force behind gas emission and if the gas saturation is high, it will be enacted more quickly. | |

| 111 | 316 |

[The FH seam] is stratigraphically a long way above the [Goonyella middle] seam (170 m to 210 m) but test boreholes into old goafs show it to have degassed ~19%. Because the gas reservoir is so large, that represents 29% of the total gas emitted from the seams above and below the [Goonyella middle]

seam. Also see Figure 36 in the Board of Inquiry Report Part II. | |

| 111 | 317 | Figure 36 in the Board of Inquiry Report Part II. | |

| 113 | 323 |

This is where relaxed strata wells could be significant in diverting gas that would otherwise find its way into the goaf. Rather than intensify the spacing of [tailgate] goaf wells as was done for LW104, drill a row of relaxed strata wells ahead of mining (eg near panel centre, 50 m apart) with cemented casing to the top of the FH seam and slotted conduit to well bottom at the base of the QB seam. These relaxed strata wells address the unique nature of the gas reservoir at [Grosvenor coal mine] – high gas reservoir size of roof coal, high gas saturation and desorption pressure. These wells would tap a large, high purity gas resource. Modelling of potential gas quantities should be carried out to plan gas extraction capacity and potential utilisation. Such wells should impact by significantly reducing gas emitted from sources that provide around half the total gas emission ([Figure 36 in the Board of Inquiry Report Part II] “Gas Emitted” column, [Fairhill], QA, QB seams). | |

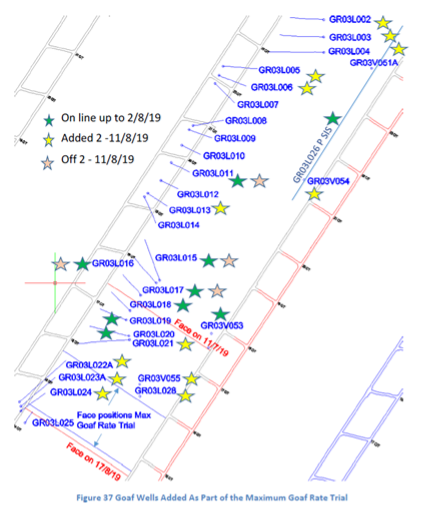

| 114 | 327 |

The added goaf wells compromise two types (yellow stars, Figure 37): – Six existing distal wells (670 m to 1030 m back from face) involving reconnection – Six wells near the face involving progressive new connections  | |

| 114 | 328 | This “maximum goaf rate trial” had a large bearing on the approach adopted to goaf drainage in LW104, namely – a halving of the [tailgate] well spacing. | |

| 116 | 337 |

There is a conflict between the management of high gas make and spontaneous combustion. … Management of these two major hazards represents a compromise, good practice in mining regarding one of the hazards generally represents bad practice concerning the other. | |

| 118 | 346 |  | |

| 119 | 351 | Grosvenor has achieved and is planned to achieve high production rates. Hence whilst 25 m3/t longwall [specific gas emission] is not exceptionally high in industry terms, mines which exhibit a higher [specific gas emission] would typically be producing 3-6 million tonnes per annum (Mtpa). | |

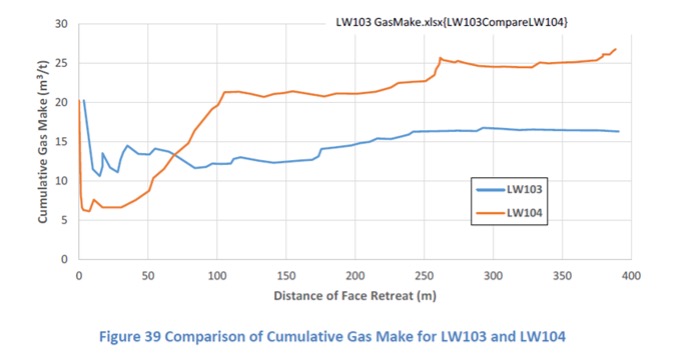

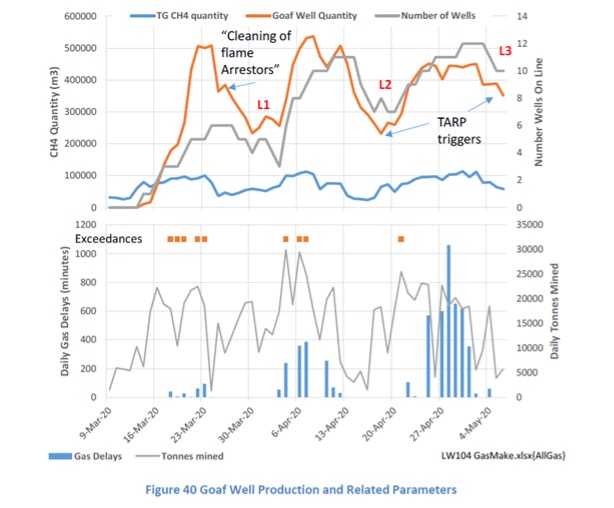

| 120 | 353 | Figure 40 in the Board of Inquiry Report Part II. | |

| 120 | 355 | Figure 40 in the Board of Inquiry Report Part II. | |

| 120 | 356 |  | |

| 120 | 357 |

Compare the following with LW103 over its initial retreat distance of 390 m: – Gas make for LW103 was 65% less, the difference being in goaf well production. – LW103 had no exceedances compared to LW104 with 14 exceedances. – Only 1 of 12 goaf wells was shut off in LW103 compared to 10 of 20 in LW104. | |

| 121 | 358 | Figure 41 in the Board of Inquiry Report Part II. | |

| 122 | 359 | Figure 42 in the Board of Inquiry Report Part II. | |

| 123 | 362 | Figure 43 in the Board of Inquiry Report Part II. | |

| 124 | 368 | Figure 44 in the Board of Inquiry Report Part II. | |

| 125 | 369 | Some people would argue that there is only a need to manage the mean gas emission figures. This would be a flawed argument, if gas emission is managed to the mean, around half of the time the system would not be capable of performing to specification and gas exceedances would inevitably result. | |

| 125 | 370 | Figure 45 in the Board of Inquiry Report Part II. | |

| 126 | 371 | Figure 46 in the Board of Inquiry Report Part II. | |

| 127 | 372 |

It can be seen that the [Post drainage capture efficiency – PDCE] was generally in the 80% range, occasionally above 90% and below 80%. Figure 47 in the Board of Inquiry Report Part II. | |

| 127 | 373 | These [Post drainage capture efficiency – PDCE] figures are considered to be typical of a post-drainage system in the [Goonyella middle seam]. | |

| 127 | 375 | It is clear that at Moreby’s predicted gas emission rates, pre-drainage of the P Seam would be a marginal requirement. At actual gas emission rates, it would be close to essential. | |

| 128 | 377 | Figure 46 in the Board of Inquiry Report Part II. |

Chapter 6

| Chapter | Page | Footnote | Content in Expert material |

|---|---|---|---|

| Chapter 6 | 179 | 569 | Figure 85 in the Board of Inquiry Report Part II. |

| 181 | 571 | The [standard operating procedure – SOP] for LW104 second workings provided a typical longwall tube bundle layout at figure 50 on page 52 of the SOP [Figure 88 in the Board of Inquiry Report Part II]. This figure identifies the proposed locations for tube bundle monitoring points. At the time of the explosion on 6 May all the tubes had been established other than the proposed tube in 34 [cut-through – ct] C-B in the tailgate. It has been identified that there were differences in the gas analysis from the 3-4 ct tube and the 400 m tube which were attributed to the flow of gases in C heading in the tailgate. Not having this tube in position for the operation of the longwall led to key data being not available. | |

| 182 | 572 | Content spans three pages and is too extensive to reproduce. | |

| 182 | 574 &576 | Figure 89 in the Board of Inquiry Report Part II. | |

| 184 | 582 | There is a history of spontaneous combustion events in the Goonyella Middle seam at North Goonyella and Moranbah North reported to the inspectorate. | |

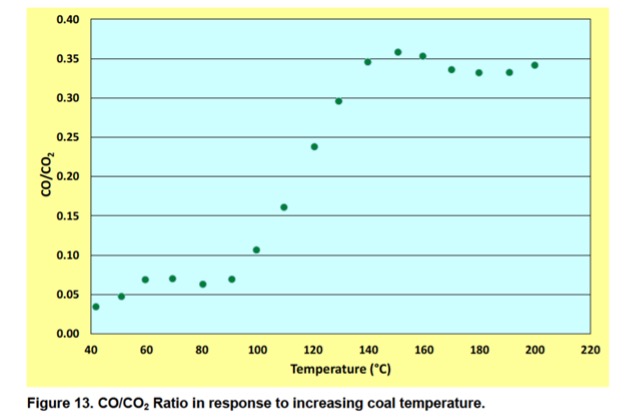

| 189 | 608 |

Graham’s ratio can be particularly useful for predicting the progression of a heating as it is able to compensate for dilution of seam gases and air. Graham’s ratio is prone to being underestimated in goafs due to excess nitrogen. This excess nitrogen could be from inertisation. This potential underestimation

should be considered when looking at Graham’s ratio values. … CO/CO2 ratio is a common ratio used as an indicator of oxidation intensity. This ratio is unaffected by dilution with excess nitrogen (in contrast to Graham’s ratio), however seam gas dilution containing carbon dioxide will affect the ratio. | |

| 191 | 611 |  | |

| 191 | 615 | Figure 94 in the Board of Inquiry Report Part II. |

Chapter 7

| Chapter | Page | Footnote | Content in Expert material |

|---|---|---|---|

| Chapter 7 | 204 | 664 | Figure 99 in the Board of Inquiry Report Part II. |

| 225 | 807 | Shaft No.6 fan installation is an exhausting application. | |

| 225 | 808 | Figure 101 in the Board of Inquiry Report Part II. | |

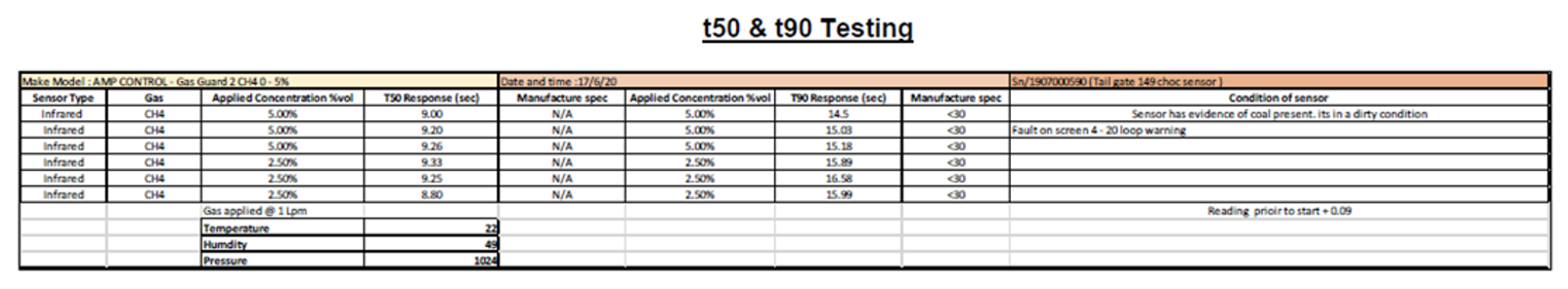

| 227 | 813 | The mechanism of the explosion appears to have been a near-instantaneous increase in methane concentration in the general body of the longwall face. This is evidenced by the rapid increase in methane gas concentration at the 149 shield methane sensor from less than 0.5% to approximately 4.3% almost instantaneously. The telemetry methane concentration measurement flat lined at 4.3% approximately and it is likely that the sensor was ‘poisoned’ and the real reading was 5% methane or greater, otherwise the explosion would not have propagated towards this point. | |

| 227 | 814 |  |

Chapter 8

| Chapter | Page | Footnote | Content in Expert material |

|---|---|---|---|

| Chapter 8 | 229 | 818 | Figure 36 in the Board of Inquiry Report Part II. |

| 230 | 822 | This report will review the geotechnical environment and the prevailing ground conditions on the lead up to the methane ignition event which occurred on LW 104’s face in Grosvenor Mine on the 6th May 2020 and if deemed relevant, will provide comment on the geotechnical factors deemed likely to be associated with the ignition event. | |

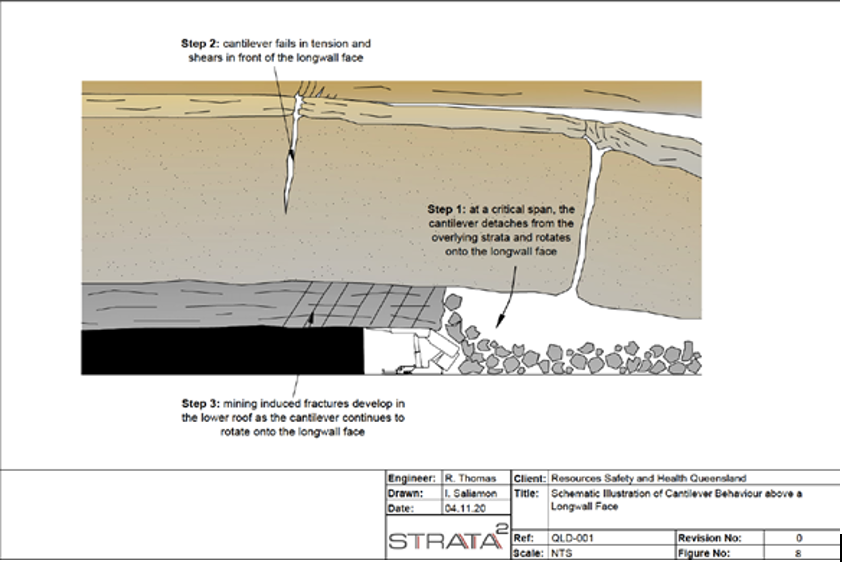

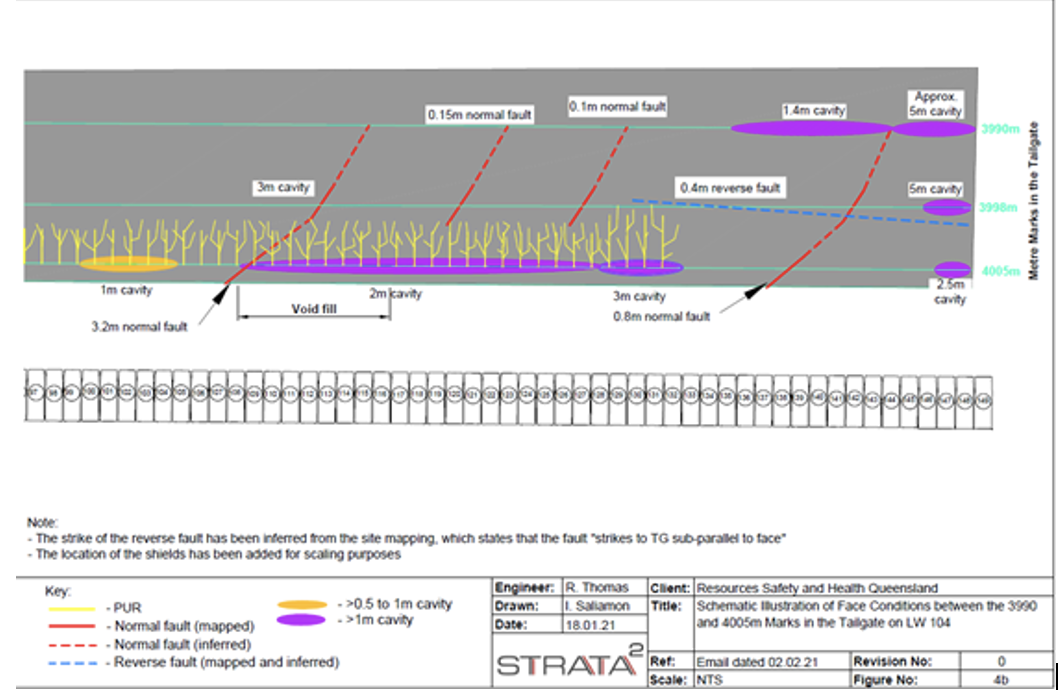

| 233 | 831 | The key geotechnical factors associated with airblasts are (i) thick and competent rock types in the near-seam overburden that have the potential to span and fail en masse some distance into the goaf and (ii) a limited thickness of interburden between the extraction horizon and the base of the spanning unit, such that a pathway exists for the goaf gases to displace into the mine workings [see Figure 105 in the Board of Inquiry Report Part II]. | |

| 234 | 832 | As to what constitutes a limited thickness of interburden, whilst general experience suggests that for a windblast to occur the thickness of the interburden needs to be less than two times the height of the adjoining gate roads (NSW Department of Primary Industries, 2007), for smaller scale airblast type events, two parameters need to be satisfied; namely (i) the presence of an air gap between the goaf material and the base of the spanning unit, such that the overlying unit is able to detach and in effect, freefall onto the goafed material below and (ii) some form of pathway is present to connect the goaf to the mine workings – note: the magnitude of an airblast is also in part related to the number of roadways located in and around the neighbouring area of goaf, as the ensuing build-up in air pressure will tend to dissipate, if the air stream is able to vent through multiple adjoining roadways. | |

| 234 | 834 | Figure 105 in the Board of Inquiry Report Part II. | |

| 235 | 837 | As to what constitutes a thick and competent rock type, in terms of windblast potential, the NSW Windblast Guideline specifies massive units in excess of 10m in thickness and notes that “irregular windblast events can also occur when thinner beds exist. | |

| 236 | 838 | Figure 106 in the Board of Inquiry Report Part II. | |

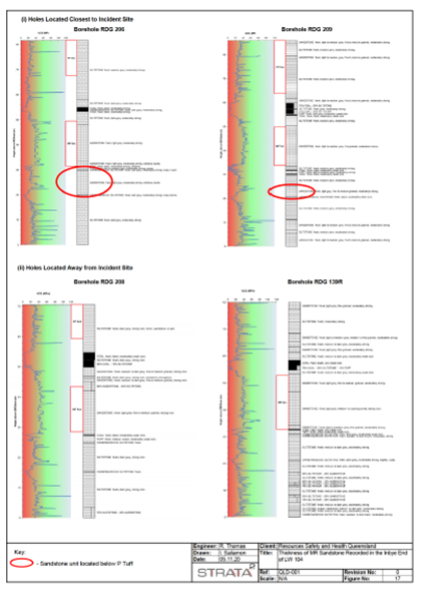

| 237 | 841 | In regard to the presence or otherwise of thick competent units of sandstone in the near-seam overburden at the incident site (i) recourse was made to geophysical sonic logs, sonic-derived [unconfined compressive strength] data and chip logs and (ii) from this information, a unit was determined as being massive, if it portrayed a near vertical sonic trace and did not therefore show any pronounced and consistent changes in rock mass strength that could otherwise indicate a change in rock type and/or a more bedded rock type [see Figure 107 in the Board of Inquiry Report Part II]. | |

| 237 | 843 | From the above, it is therefore possible to conclude that (i) the MP Sandstone is a thick and competent unit which would be expected to retain some spanning ability and so behave as a cantilever when located in the goaf and (ii) the PP Sandstone is either not present or located too high into the roof to be of any material relevance to this assessment. | |

| 237 | 844 | Figure 107 in the Board of Inquiry Report Part II. | |

| 237 | 845 |  | |

| 238 | 846 | The MP Sandstone is a) between 15 and 22m thick, and is located 32 to 35m above the GM Seam at the ignition site and b) not present in the first 400m of LW’s 101 and 102 and in the first 400m of LW 103, was no more than 8 to 12m thick and located between 37 and 43m above the [Goonyella Middle] Seam. | |

| 238 | 848 | …as a general guide, a rock with [an unconfined compressive strength] of <5 MPa can be classed as very weak, >5 to 25 MPa as weak, >25 to 50 MPa as moderately strong, >50 to 100 MPa as strong and >100 MPa as very strong. | |

| 239 | 849 | Figure 108 in the Board of Inquiry Report Part II. | |

| 239 | 850 |

Whilst it is accepted that a cantilever located immediately above a longwall face will eventually fail as the length of the cantilever increases with ongoing retreat (see Figure 8), the mapped presence of a reverse fault at a sub-parallel angle to the face on the 4th of May 2020 when the face was located

at the 3997m mark (i.e., 6m prior to the ignition) would have not only severely weakened the cantilever, but also increased the cantilever’s tendency to fail in a sudden manner. | |

| 239 | 851 | Figure 109 in the Board of Inquiry Report Part II. | |

| 240 | 852 | Furthermore, whilst it is assessed that an airblast could have still occurred had the fault(s) not been present on the face (as without the faults, the roof would have still been able to span into the goaf), it is nonetheless reasonable to assume that (i) the fault(s) would have provided a distinct plane of weakness for the cantilever to fail along and (ii) the pre-existence of a weak discontinuity, would have aided the sudden detachment of the overlying strata and the associated sudden expulsion of the goaf gases into the mine workings. | |

| 242 | 860 |

In regard to the flow path needed for the expelled gases to reach the mine workings, it is of note that in the area of the ignition (i) the MP Sandstone is located the closest to the seam, thereby reducing the amount of underlying weaker material available to bulk up and in effect fill the goaf…, (ii) compared to the first 400m of retreat in LW’s 101 to 103, the interburden between the [Goonyella middle] Seam and the base of the MP Sandstone is dominated by more silty strata, which upon failure, would be expected to bulk up to a lesser degree in the goaf…, (iii) although not classed as a massive unit, the MR Sandstone is at its thickest and in doing so, could also have spanned some distance into the goaf; thereby further reducing the amount of bulked up material present in the goaf…and (iv) the cavities reported in the tailgate end of the face would have resulted in an effective increase in extraction height and in doing so, reduced the amount of material available to bulk up in the goaf. | |

| 242 | 861 | Figure 110 in the Board of Inquiry Report Part II. | |

| 243 | 862 | Figure reproduced in footnote 845 above. | |

| 242 | 863 |

…although not classed as a massive unit, the MR Sandstone is at its thickest and in doing so, could also have spanned some distance into the goaf; thereby further reducing the amount of bulked up material present in the goaf. (full paragraph reproduced under footnote 860 above). | |

| 244 | 864 |  | |

| 245 | 869 | Further to the above, the sudden 10 to 175 bar increase in leg pressure measured on Shields #139 to #149 (again located in the tailgate end of the face) is consistent with the sudden failure of a sizeable overlying roof unit [see Figure 111 in the Board of Inquiry Report Part II]. | |

| 248 | 875 | Figure 112 in the Board of Inquiry Report Part II. | |

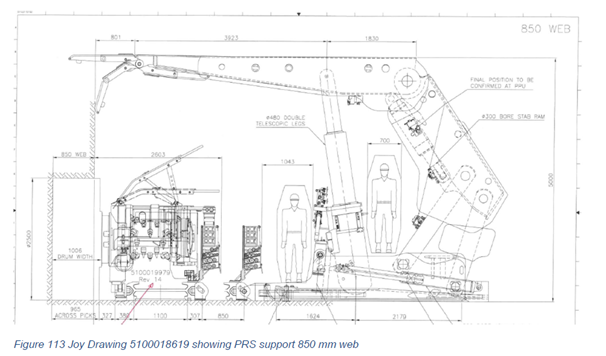

| 249 | 880 & 881 | Figure 113 in the Board of Inquiry Report Part II. | |

| 251 | 886 | Figure 115 in the Board of Inquiry Report Part II. | |

| 251 | 887 |  | |

| 251 | 888 |

GRO4V009.5 The following observations were made: – This goaf well was active from the 1st of May. – Methane levels were typically between 30% and 60% during this period. Oxygen was between 5 and 10%. – A significant decrease in methane and increase in oxygen is noted immediately before the event. – The [carbon dioxide] from this location does not exceed 40 [parts per million] even subsequent to the ignition on May 6th. | |

| 252 | 889 | Figure 116 in the Board of Inquiry Report Part II. | |

| 253 | 891 | Figure 117 in the Board of Inquiry Report Part II. | |

| 254 | 894 | Figure 117 in the Board of Inquiry Report Part II. | |

| 256 | 898 | Figure 119 in the Board of Inquiry Report Part II. | |

| 257 | 899 | Figure 120 in the Board of Inquiry Report Part II. | |

| 258 | 901 | Figure 121 in the Board of Inquiry Report Part II. | |

| 259 | 902 | Figure 122 in the Board of Inquiry Report Part II. | |

| 260 | 904 | Figure 123 in the Board of Inquiry Report Part II. | |

| 260 | 905 | Figure 124 in the Board of Inquiry Report Part II. | |

| 261 | 906 | Figure 125 in the Board of Inquiry Report Part II. | |

| 261 | 907 | Figure 121 in the Board of Inquiry Report Part II. | |

| 262 | 908 | Figure 126 in the Board of Inquiry Report Part II. | |

| 263 | 912 | Figure 127 in the Board of Inquiry Report Part II | |

| 264 | 913 | Figure 128 in the Board of Inquiry Report Part II | |

| 265 | 918 | Figure 129 in the Board of Inquiry Report Part II. | |

| 266 | 919 | Figure 130 in the Board of Inquiry Report Part II. | |

| 267 | 921 | Figure 132 in the Board of Inquiry Report Part II. | |

| 268 | 923 | Figure 133 in the Board of Inquiry Report Part II. | |

| 269 | 924 | Figure 134 in the Board of Inquiry Report Part II. | |

| 270 | 928 | Content spans four pages and is too extensive to extract. | |

| 270 | 930 |  | |

| 271 | 936 | Content spans three pages and is too extensive to extract. | |

| 271 | 937 | Figure 134 in the Board of Inquiry Report Part II. | |

| 271 | 938 | Figure 135 in the Board of Inquiry Report Part II. | |

| 272 | 939 | Figure 136 in the Board of Inquiry Report Part II. | |

| 273 | 940 | Figure 137 in the Board of Inquiry Report Part II. | |

| 274 | 941 | Figure 138 in the Board of Inquiry Report Part II. | |

| 274 | 942 | See table above under footnote 930. | |

| 274 | 943 |  | |

| 275 | 945 | Figure 139 in the Board of Inquiry Report Part II. | |

| 275 | 946 | Spontaneous combustion indicators were detected in the tailgate goaf wells. Limited samples were taken from the tailgate side drainage wells within the week before the 6th of May despite some of these locations measuring 50-100 [parts per million of carbon monoxide] on the real time skids (Martin Watkinson 2020). The samples that were taken contained trace levels of ethylene. No samples were taken from GRO4V009, GRO4V009.5 or GRO4V010 before the event, which were potentially as relevant as the goaf stream samples for detection of oxidation activity. Sampling from the goaf wells was insufficient to determine the intensity of spontaneous combustion activity in the days before the event. | |

| 275 | 947 | Figure 140 in the Board of Inquiry Report Part II. | |

| 276 | 948 | [Gas chromatograph] corrected real time response from the skid at this location [GRO4V007] readings show an increase in [Graham’s Ratio] on the 5th of May. | |

| 276 | 949 | Figure 141 in the Board of Inquiry Report Part II. | |

| 277 | 950 | Figure 142 in the Board of Inquiry Report Part II. | |

| 277 | 951 | Figure 143 in the Board of Inquiry Report Part II. | |

| 278 | 952 | Figure 144 in the Board of Inquiry Report Part II. | |

| 278 | 953 | Figure 145 in the Board of Inquiry Report Part II. | |

| 279 | 954 | Immediately post event the highest [carbon monoxide – CO] recorded at the skid data from this location [GRO4V009.5] was about 36 [parts per million – ppm]. This is in contrast with skid GRO4V009 nearby and further back in the goaf which detected over 1000ppm CO in the bag sample taken at 15:05. | |

| 280 | 961 | See tables above under footnotes 930 and 934. |

Chapter 9

| Chapter | Page | Footnote | Content in Expert material |

|---|---|---|---|

| Chapter 9 | 288 | 987 | Ignitions caused by hand tools or coal cutters hitting rock are also quite numerous. However, explosions caused by rock on rock interactions from falls in the goaf are rare (or have been rarely identified). |

| 288 | 988 | A review of case histories found ignition in coal mines caused by rock falls were generally rare in occurrence compared to other sources of ignition. Explosions caused by this phenomenon have not been reported in Australia but there are various reports of it having occurred in other countries. | |

| 288 | 989 | Content spans nine pages and is too extensive to extract. | |

| 288 | 990 |

The rock material was the greatest factor in determine the incendivity of steel on rock impacts. … From both rubbing friction and impact experiments, it is clear that the rock composition is a key factor influencing the incendivity of rock-on-rock interactions. | |

| 289 | 994 |

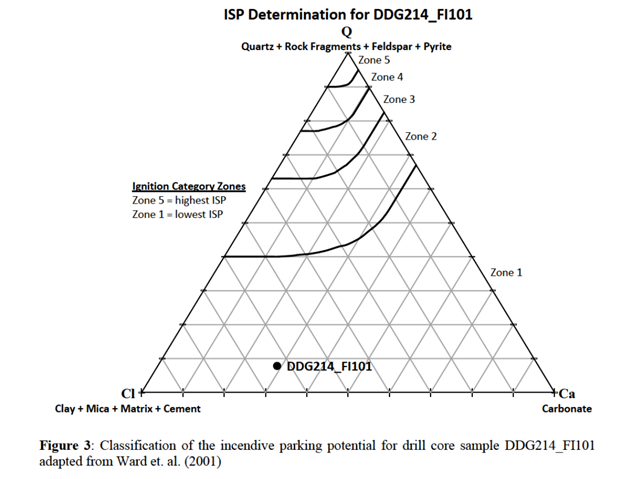

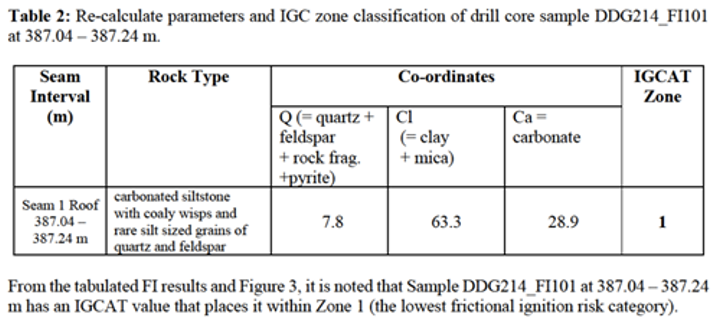

A thin section was prepared from the drill core sample to permit detailed mineralogical counting using transmitted polarised light microscopy. An approximate composition was determined, expressed in volume percent and based on identification and counting of the microscopically observed components at each of 100 widely spaced observation points within the thin section. The results were then recalculated to yield the necessary parameters; Quartz + rock fragments + feldspar + pyrite, Clay matrix cement + mica + clay pellets, and Carbonate but no organics for comparison with a triangular classification diagram supplied by C. R. Ward from the University of NSW. Based on the calculated parameters, each sample was then assigned an appropriate [ignition categorisation – IGCAT] value (a measure of perceived incendive sparking potential) as designated by zones within Ward’s triangular diagram (Fig. 3). Ward’s ternary diagram defines five IGCAT zones, with Zone 1 corresponding with the lowest incendive potential and Zone 5 corresponding with the highest potential.  | |

| 289 | 995 |  | |

| 293 | 1015 | The probability of ignition by steel on rock interactions during the process of double chocking has been deemed negligible due to the low movement velocities well below those required for ignition in the literature. | |

| 294 | 1017 |

Rubbing friction of steel on steel will cause ignition of methane-air mixtures only if the friction is sufficient to raise the temperature to a white heat (i.e. greater than 1000°C). A greater risk is rather coal dust smouldering at temperatures above 180°C or incendive debris caught between fast moving

surfaces. … The probability of ignition of firedamp at the [armoured face conveyor] (which moves at 1.84 m/s) was deemed as negligible due to the low operational velocities which would not be able to create incendive sparks or the white-hot surfaces required for ignition. | |

| 294 | 1018 | The evidence indicates that the flamefront originated in the vicinity of Chock 111. Evidence seen in the clothing from some personnel provides consistency, with fire appearing to approach from the right of Injured coal mine worker 5 and from the left of Injured coal mine worker 3 and Injured coal mine worker 1. The evidence indicates that flame travelled from the rear to front walkways. | |

| 294 | 1033 |

The Simtars test laboratory was used to simulate the underground roof support system. Subsequent testing was conducted on the operation of the roof support system using a test simulator and each control function was tested for correct operation using the cables and equipment from each roof support system

supplied to Simtars. Individual testing of cable insulation did identify some cables with low insulation resistance [IR] but no faulty or open-circuited cables were detected. … The simulation of the operation of the roof support system did not identify any abnormal function. The mains-powered cables were examined and tested for insulation resistance. There were no short or open circuits observed during the cable examination and the IR tests indicated good insulation properties. | |

| 297 | 1042 | The testing of cap lamps did not reveal any issues or non-compliance. The short circuit test performed showed the protection circuitry to be operational (overload detection) and stayed in a safe mode until a software reset was performed. | |

| 297 | 1043 | Content spans five pages and is too extensive to extract. | |

| 300 | 1057 | Figure 150 in the Board of Inquiry Report Part II. | |

| 301 | 1060 |  | |

| 301 | 1062 | Figure 152 in the Board of Inquiry Report Part II. | |

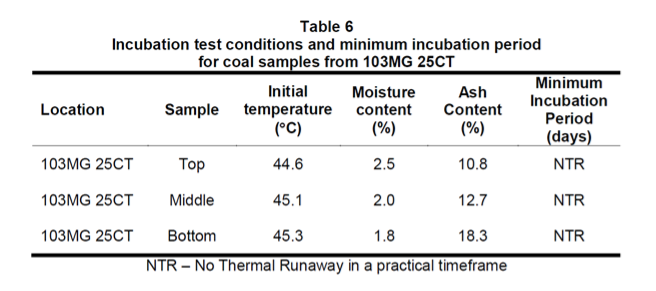

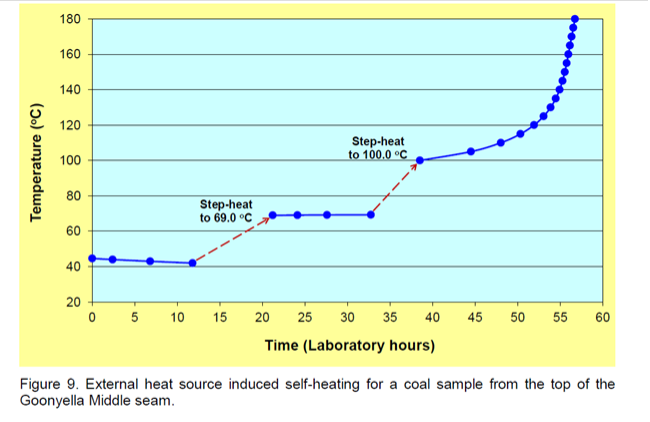

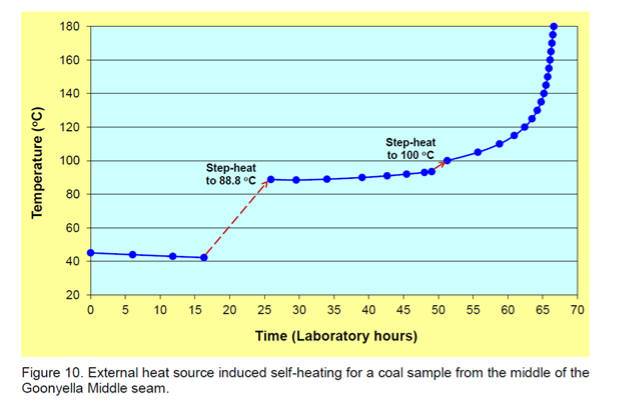

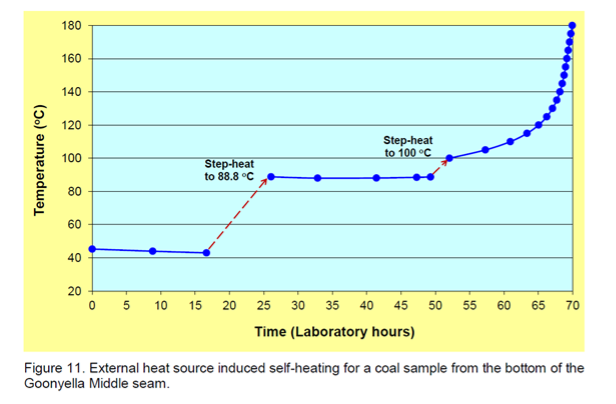

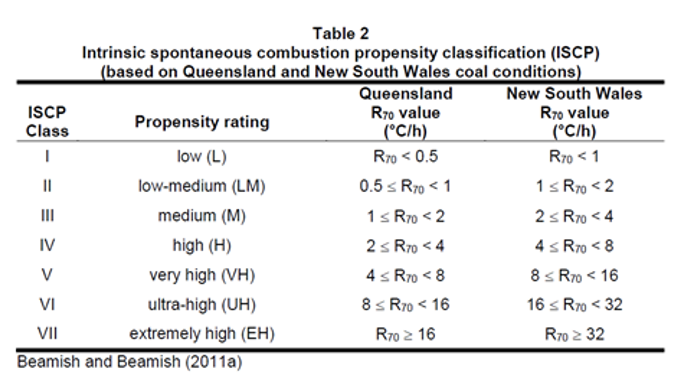

| 303 | 1065 | There is one possible situation that could lead to a spontaneous combustion event…This is when the coal comes into contact with an external heat source, such as a curing compound (for example [polyurethane resin]). Under these circumstances the temperature of the coal may be artificially raised beyond the point where the natural inhibition from moisture and mineral matter in the coal is overcome and thermal runaway prevails. This can be seen from the results of a step-heat test [shown in Figure 154 in the Board of Inquiry Report Part II] applied to a sample from Grosvenor Mine to obtain the RIT value. Where this situation is likely to be present, vigilant gas monitoring should be adopted to identify the presence of any elevated temperature in the coal using indicator gas trends. | |

| 304 | 1066 | For the samples from [103 maingate 25 cut-through] at a mine ambient temperature of approximately 45°C, incubation to thermal runaway is not possible in any practical timeframe. However, if the coal comes into contact with an external heat source for a period of time, self-heating to thermal runaway is possible. | |

| 304 | 1067 |

The result of No Thermal Runaway for each of the samples, if a loose pile of coal is formed at critical thickness with sufficient continuous air supply and minimal heat dissipation as shown in Table 6, is consistent with the low intrinsic reactivity of each of the samples and the moisture content in